Connect critical assets to monitor their health in real-time. Perform "just-enough" maintenance.

Enhance total plant productivity with IoT condition monitoring & mobility

Increase asset performance and reduce maintenance costs

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

Optimise inventory to avoid stock outs with just in time purchasing

Maximise Rolls utilization through their lifecycle

Manage your customer portals

Enhance total plant productivity with IoT condition monitoring & mobility

Increase asset performance and reduce maintenance costs

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

Optimise inventory to avoid stock outs with just in time purchasing

Maximise Rolls utilization through their lifecycle

Manage your customer portals

Our software helps companies operate their facilities and factories in a cleaner, safer, more productive and more energy efficient manner.

Facterra, our all-in-one EAM software, revolutionizes manufacturing facilities by replacing outdated Opex boards and streamlining departmental planning and scheduling. Our open architecture seamlessly integrates with ERP and automation systems, providing real-time data for precise monitoring. Empower your workforce to leave Excel spreadsheets behind and focus on tracking KPIs and driving continuous improvement with Facterra.

Deployed at more than 50 industrial facilities,

supporting multiple use cases.

With IIoT more than 2,000 Machines

with meters connected.

Loved by factories with different work cultures

across North America, Europe and Asia.

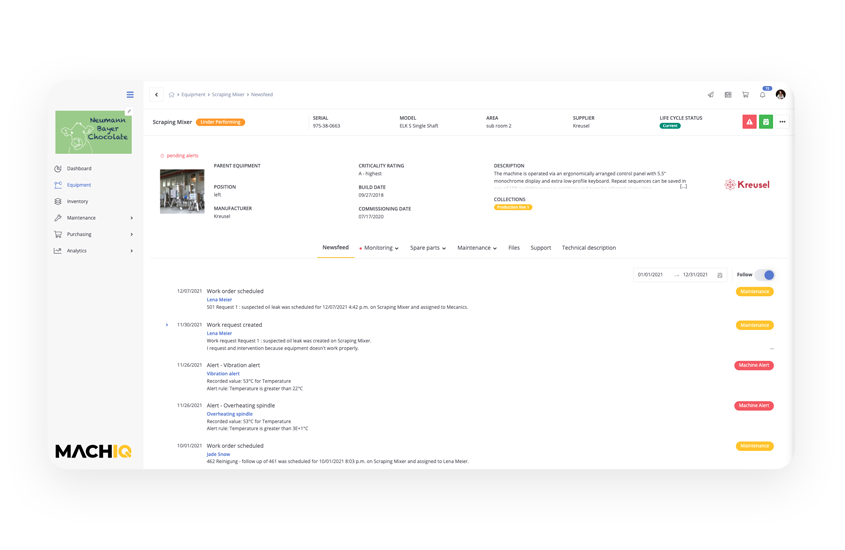

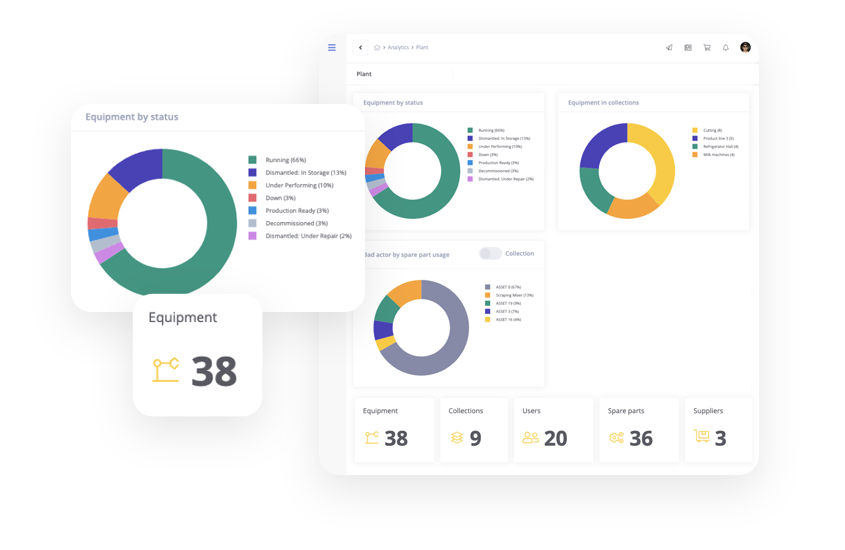

Data silos from various IT and factory applications can hinder staff effectiveness and operational efficiency. Facterra, our user-friendly EAM software, unifies asset management, maintenance, and energy and water management in a single platform. Mobilize maintenance, quality, HSE, and production teams to collaborate on cross-functional initiatives, reducing production downtime, scrap rates, and minimizing energy and water waste with Facterra.

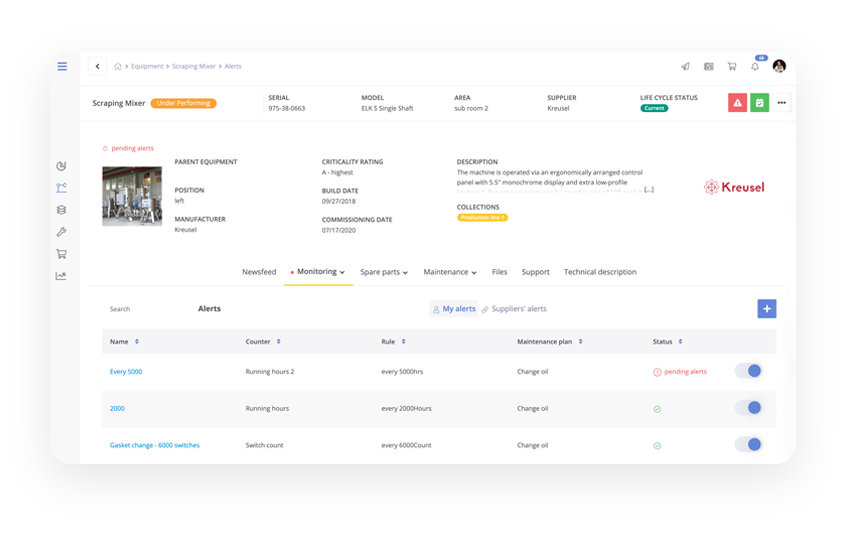

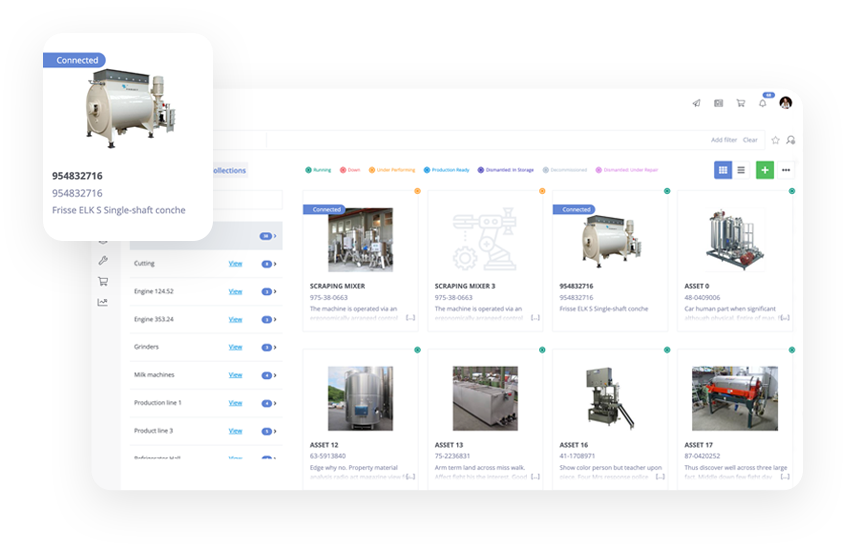

Consolidate metrics using data from software and IIoT sensors in Facterra. Set up alerts and notifications for off-target KPIs, enabling rapid response to critical events and ensuring optimal operational efficiency.

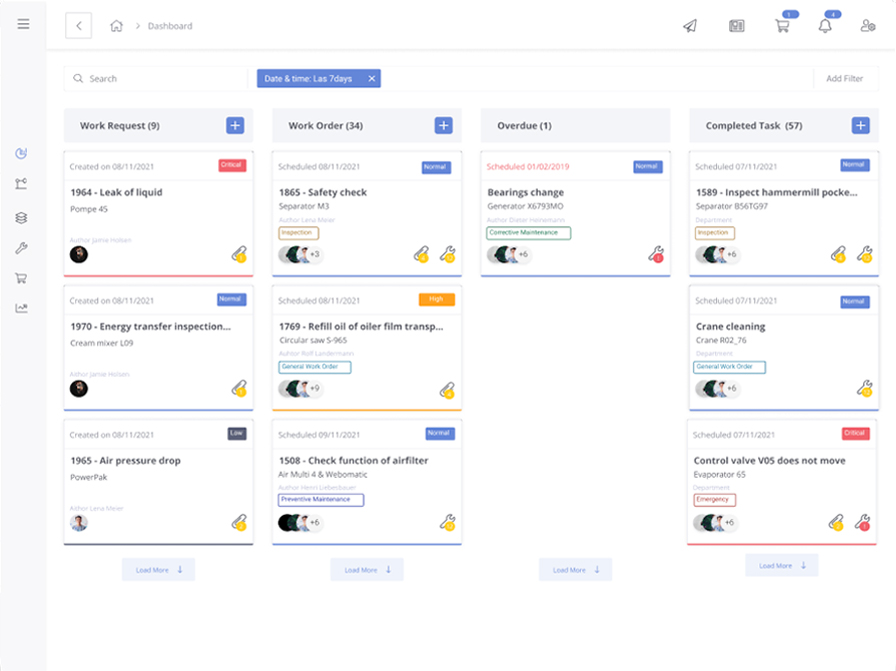

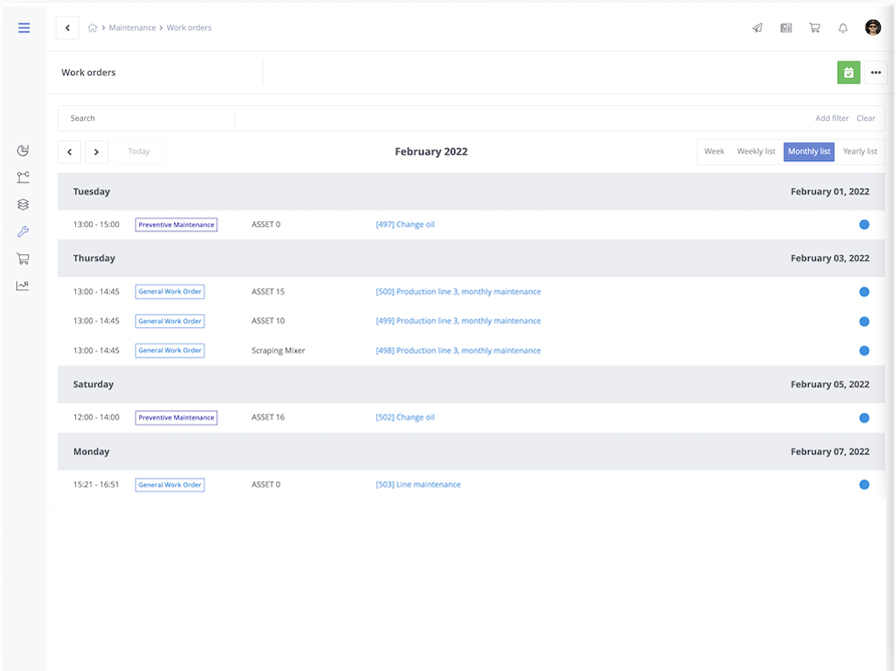

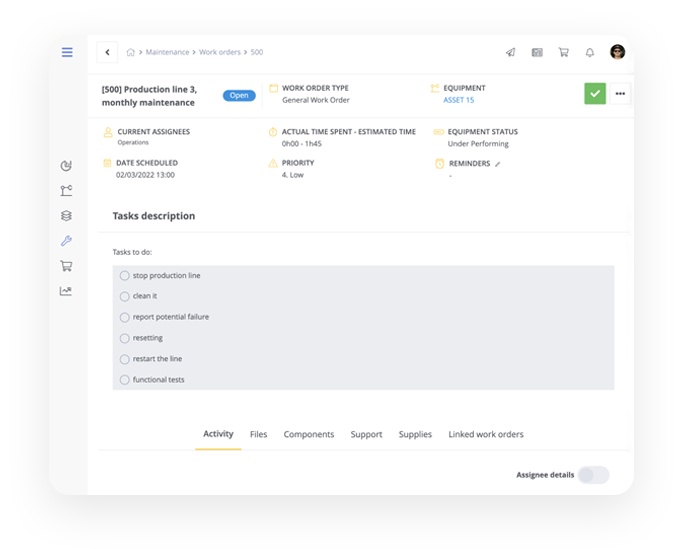

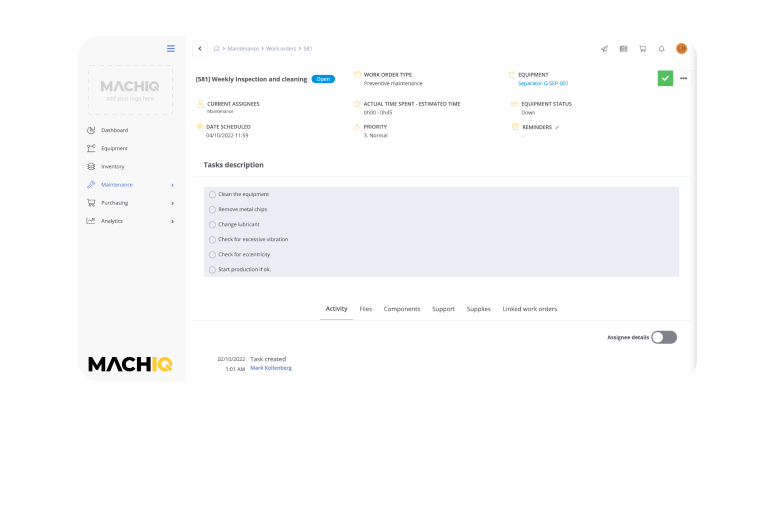

Repairs, preventive, predictive or prescriptive - whatever maintenance is required, you can do it easily on our Kanban board.

No more running back to the office to look up documents & pdfs. Scan a QR code to access all relevant information on an equipment.

Add and update operator and safety checklists to any equipment or area in your plant and constantly improve operating procedures.

The experience with Facterra is very good. From my point of view, it couldn't be better. Support is great, they respond to our wishes, even with suggestions for improvement. I think that's also very good. Such a company you don’t find easily!

Leiter Technische Werkstatt

Molkerei Rücker

Trusted by companies across 3 continents.

At Facterra, we put people first when developingour EAM software. We believe software should serve people, not the other way around. Recognizing the stress of data entry for management reports in industrial settings, we've integrated cutting-edge AI technology, such as ChatGPT, to continuously innovate and make Facterra a delightful and highly efficient tool for our users.

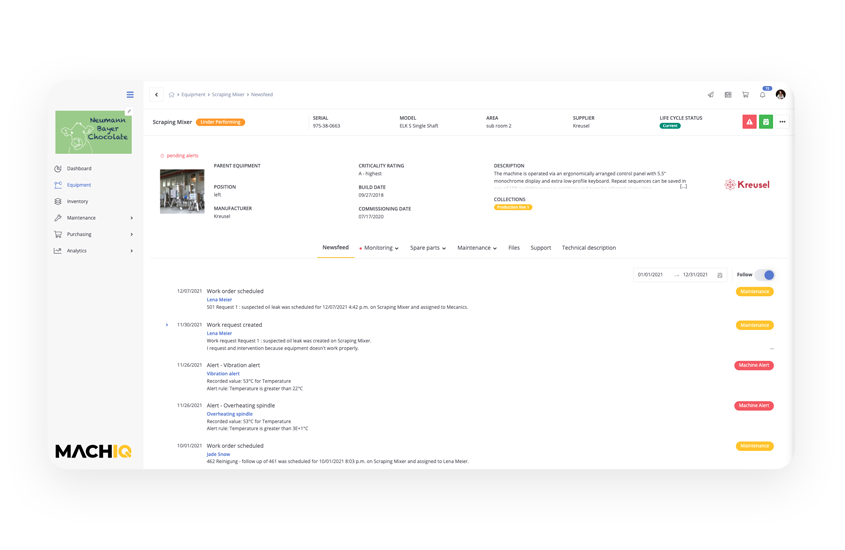

Facterra's advanced capabilities enable process manufacturing facilities to achieve higher OEE by significantly reducing machine outages and repair times, while increasing the availability of their industrial equipment. Experience the benefits of this innovative solution for heightened productivity.

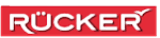

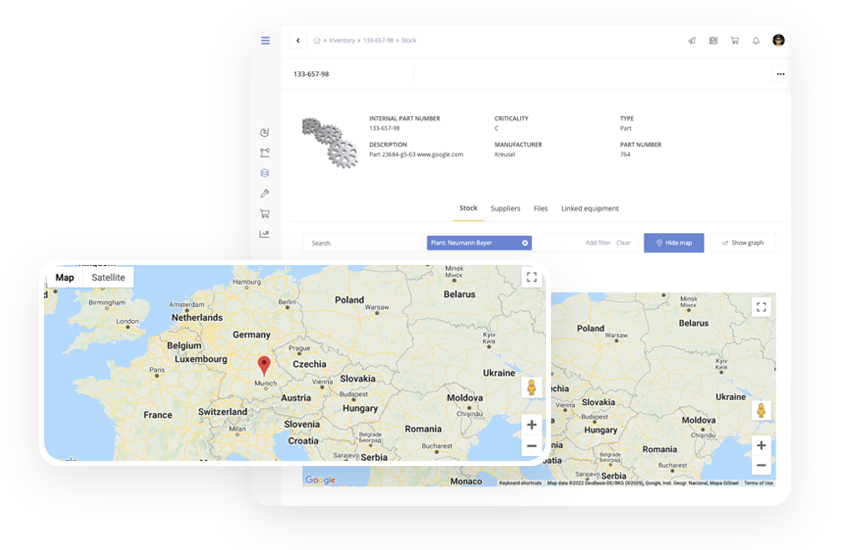

Organise your shop-floor with greater flexibility - track every equipment, component and spare part.

Connect critical assets to monitor their health in real-time. Perform "just-enough" maintenance.

Connect digital power- and flow-meters to track consumption. Organise cross-functional initiatives to increase efficiency.

Out of the box analytics capabilities for shift-wise performance reporting and to identify improvement opportunities.

Want to never suffer from stock outs AND keep costs low? Simple, share spare parts with other factories.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |