- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Product

- Solutions

- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Digital Factory

For the last couple of decades, as service revenue grew in importance, industrial machinery OEMs rightfully focused on their large named accounts. Adhering to the 80-20 principle in increasing penetration of strategic accounts has been hugely successful but as large customers start to consolidate purchasing, not only are the plump margins starting to fade, growth has also hit a ceiling and OEMs are increasingly forced to look elsewhere to deliver the next billion in revenue growth. In this article series, I focus on the roadblocks that need to be addressed if OEMs are to build a fast-growing but profitable business out of servicing the proverbial long-tail.

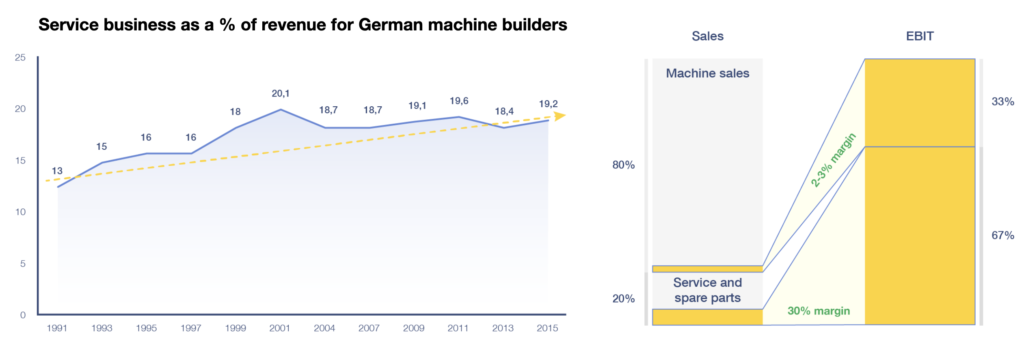

The service business stakes

Here is a great infographic that Dr. Daniel Rohde built for us based on his research of different studies conducted on the service business of German machinery companies. One can see the outsized role that service revenue plays in the P&L of these OEMs. I am assuming here that mid-to large sized machinery companies from Strong OEM Countries like Italy, Switzerland, Austria and the Nordics are on similar trajectories themselves.

Industrial OEM Profit Pool Based on our conversation with industry leaders, we believe that their known customer-base that is consuming services has saturated. This is also driving M&A activity in the industry as the rationale for most acquisitions tends to be offer portfolio expansion so that the OEM’s can sell more to their captive customer base.

New machine sales channels limiting the service revenue potential

When the discussions focused on services, what we learnt is that most OEMs capture less than 20% of their install-base i.e. they know which companies are operating less than 20% of the machines that they have sold. This is primarily due to the sales channels that they employ for new machine sales.

Often, small and mid-sized OEMs in the F&B and process industries sell their machines through dealers and to EPC/Plant Engineering companies that commission the plants for the industrial operators. As a result, they rarely maintain a direct relationship with the operators. The impact on the service potential of these customers is outsized. Any services that such customers consume has to be routed through the intermediaries.

This also means that in fast growing geographies where the service maturity of dealers is poor, OEMs record almost no service revenue from the end users of their machines. Then there are also the buyers of used machines. These buyers have more advanced service needs given that machines that are sold in the used machines market are generally past warranty and tend to be 8 to 20 years old. These buyers are completely invisible to the OEMs since they procure from specialist refurbishers.

What this demonstrates without a doubt is that OEMs are leaving a lot of service needs unaddressed. All other things being equal, service revenue could easily be between 4x-6x its current levels if the elusive long tail can be captured. The topic has grown in urgency in the Covid-19 environment where capital investments have slowed down and customers are placing fewer orders for spare parts since their plants are operating at lower utilisation levels. There is an urgent need to expand the customer base to maintain revenue levels.

You can’t sell to customers that you don’t know. So how do you identify these customers? Most channel partners are very wary of sharing this information out of the fear of being short-circuited. In this series of posts, I will offer recommendations on how OEMs can identify and engage with the long-tail operators of their machines to build cost efficient processes at scale to address their service demands profitably.

PREV

Why digital plant projects fail (and what to do to succeed)

NEXT

The long-tail is where the next billion in service revenue is (Part 2)

Related Posts

The Manifesto for a New Normal

It was exactly a year ago that I returned from BrauBeviale, an international trade fair for the beverages and brewing industry and realised that I had lost my sense of taste. It was still pre-Covid-19 in the news, my doctors put it down to an inexplicable neurological cause that they couldn’t diagnose.

November 19, 2020

The Product Manager’s guide for Smart Services (Part 1)

In this series of posts, I address service product management topics around building smart services – more specifically remote monitoring

April 21, 2021

Get Started

Interested in evaluating the

product for your team ?We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - Digital Factory