- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

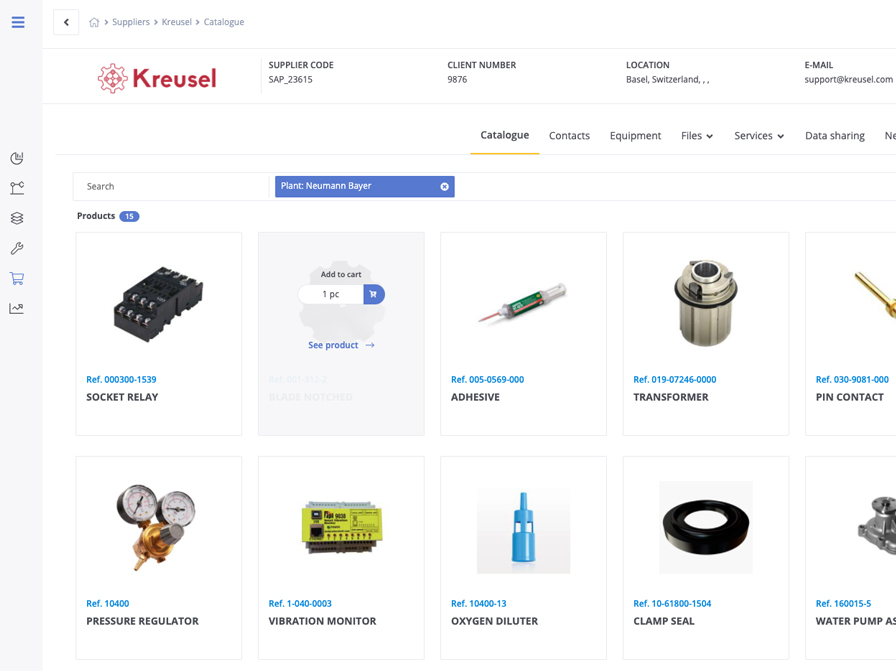

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Product

- Solutions

- By Use-case

- Digital Factory

Enhance total plant productivity with IoT condition monitoring & mobility

- Maintenance Management

Increase asset performance and reduce maintenance costs

- Digital Sustainability

Reduce the CO2 emissions of your plant and facilities & meet your SDG goals

- Spare Parts and Consumables

Optimise inventory to avoid stock outs with just in time purchasing

- Rolls Lifecycle Management

Maximise Rolls utilization through their lifecycle

- Customer Portals

Manage your customer portals

- By Industry

- Pricing

- Resources

- Company

- Digital Factory

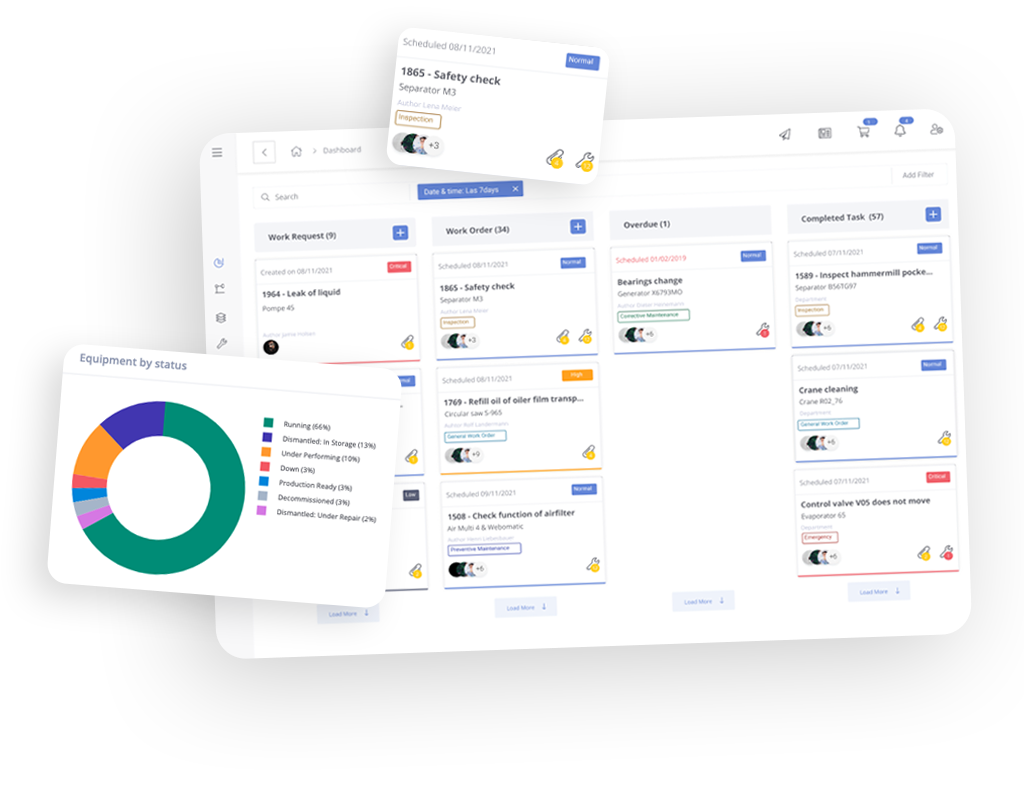

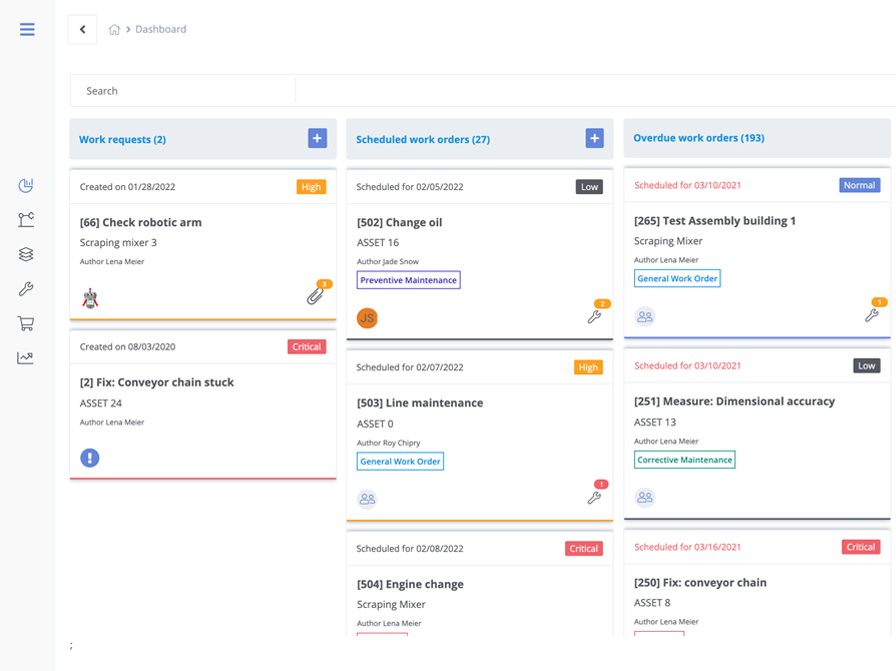

Facterra streamlines operational performance metrics and integrates them with performance improvement scheduling across productivity, asset management, energy management, quality, and health and safety departments. Offering a clutter-free user experience, Facterra provides valuable, context-driven insights while reducing manual data entry, enhancing satisfaction for both personnel and managers.

Transform data from the

shop floor into insights for

the top floorFacterra assists teams in implementing condition-based and reliability-centered maintenance (RCM) practices

By leveraging IIoT and FMECA, industrial sites optimize maintenance frequency for maximum uptime. Facterra’s built-in analytics capabilities empower customers to make data-driven decisions that effectively minimize downtime, optimize resource consumption, and reduce maintenance and utility costs.

We promise

Positive ROI in under 12 months

15%

Higher asset availability

Improvement in maintenance performance (MTTR & MTBF)

20%

Higher energy efficiency

20% reduction in electricity consumption in standby mode

10%

Leaner parts inventory

Improvement in spare parts inventory stock turn

35%

Time saved on audits

Simplified compliance with an easily searchable, digital audit trail.

The cockpit for

your digital factory.Everything that you need to enjoy higher OEE and sustainability in your operations. Nothing more, nothing less.

Asset Register

Organize your shopfloor with greater flexibility – track every equipment, component and spare part.

QR codes

Access safety checklists, machine history, documents & parts lists info on tablets & smartphones and save time.

Connected machines

Connect critical assets for real-time condition monitoring. Deploy digital power meters to identify and eliminate wasteful energy consumption.

Digital Op-Ex

Out of the box analytics capabilities to automate performance report generation and to follow-up on action plans

Kanban for scheduling

Tracking maintenance requests and scheduling work orders made easy with our drag & drop interface.

Shared inventories

Want to never suffer from stock outs and keep costs low? Simple, share spare parts with other plants.

Operator checklists

Improve operator training and reduce scrap by offering up-to-date operator manuals and rich-media training material.

Machine documents

Store all documents associated with your equipment – service history, training manuals, drawings and more.

Why companies choose Facterra

Facterra empowers companies to achieve more with less. From basic maintenance management in dairy plants to roll shop management in steel mills, and from spare parts inventory optimization to predictive maintenance and resource efficiency, our customers save millions by choosing Facterra as their go-to EAM solution.

“Very few good technicians want to work in maintenance these days.

It is difficult to make sure that our technicians have the knowledge to diagnose and solve the different kinds of problems we get with our machines.”Lack of Trained & Experienced technicians

CEO of a leading European meat processor

“When our critical machines fail, sometimes, it can take days for them to be repaired. Often, we are just waiting for information…what is really the problem and how to fix it, it would be different.”

High cost of Machine Breakdowns

Head of Maintenance at a German dairy

“We do not master our inventory – we have too many items but at the same time, we never find the parts that we need when we need to perform a maintenance job.”

Inefficient Spare Part Inventories

Head of Maintenance at a Swiss chocolatier

“I am always stressed about audits. We follow all the rules of course but with our current tools, it is a lot of effort to find the paper work to prove to the auditors that we have complied.”

Painful Audits

Owner of a Dutch vegan foods company

Get Started

Interested in evaluating the

product for your team ?We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.To find out more about the cookies we use, see our Privacy Policy

If you decline, your information won’t be tracked when you visit this website. A single cookie will be used in your browser to remember your preference not to be tracked.

Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checkbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checkbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - Digital Factory